Research studies have shown that 70% of registered dental hygienists experience hand, wrist, and/or arm pain when using a scaler. The HuFriedyGroup proactively decided to develop a scaler that would reduce this pain and the chance of hand fatigue or injury due to the hygienist’s use of repetitive pressure motions during the scaling process.

HuFriedyGroup’s designers, engineers, researchers, and SME’s collaborated with HLB to create the measuring devices and system that would allow HuFriedyGroup to test and measure the effectiveness of scalers with different design features. Iterative designs coupled with a defined measuring process were used to improve the scaler’s effectiveness. The measuring system consisted glove/pads that HLB sourced, repurposed and developed with HuFriedyGroup to fit on scaler pressure points on the testers’ fingers. The tester would then perform the scaling and the system would measure the relevant forces on the hand and the pressure exerted on the model test tooth that was developed for this purpose. These multi- dimensional simultaneous measurements were recorded and displayed be the HLB/HuFriedyGroup developed system. During the course of the scaler’s development HuFriedyGroup conducted 2.8 million tests.

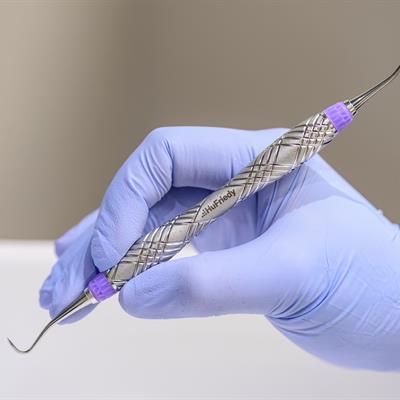

HuFriedyGroup has named this development process TrueFit Technology. The first product developed with TrueFit Technology is a scaler that reduces the hygienists required pinch force by 65% and increases the pressure on the tooth by 37%. These major advances in ergonomical design and engineering of the HuFriedyGroup scaler are expected to reduce hygienist hand fatigue and pain and improve patient comfort.

Subscribe to our newsletter for news & updates